Our story

From waste plastic to a design products

Durat manufactures design products from waste plastic. Throughout its history, the company has focused on strengthening its operations in line with the principles of the circular economy. The company has always had faith in its own work and has gone out into the world with confidence.

The idea of using waste plastic was born

Durat's story began when its founders became concerned about the amount of plastic waste being generated and the fact that usable material was ending up in landfills, harming the environment.

Kari Karppinen, the company's current Chairman of the Board and first CEO, recalls the early days:

“I worked at a bank in Turku and heard from a friend that Neste was looking for a company to develop a solid surface material based on their resin product. We thought about it, and when we realised that this would be an opportunity to utilize waste plastic, the idea became interesting.”

Kari assembled a team of financiers to back the company. During the first couple of years, some of them dropped out, leaving Kari and Ulla Tuominen as the only ones left.

“I was really keen to get involved when I found out that we could come up with a smart use for the plastic waste that's generated in industrial production. My interest in environmental issues was sparked in the late 1970s and early 1980s, when I was studying in England”, Ulla explains her background.

Born in the midst of the recession in Orimattila in 1990

In 1990, Tonester Oy was founded, an industrial hall was rented in Orimattila, and product development work began with the company's own capital.

“The early days of developing the product were quite exciting. We got good support from Neste's experts, but even they hadn't worked with solid surfaces before. However, through trial and error, we managed to do it,” say Ulla and Kari.

When Durat was born, Finland was in the midst of the deepest recession in its history. Ulla recalls those times:

"When I drove through the industrial area to our premises in the mornings, I noticed that every day fewer and fewer halls in the area had their lights on. At the times, it was terrifying to wonder how long we would be able to continue."

"Luckily, because of Kari's experience in banking, we had the view that the Bank of Finland's and the government's assurances that the markka would not be devalued might not be true. That's why we avoided currency loans, and it saved us," Ulla says, praising her long-time business partner.

In 1992, product development had progressed so far that production could begin.

A big step in the early stages was when interior design firm Sistem's Riitta and Arto Kukkasniemi chose Durat as the material for Neste's Keilaniemi extension. Among other things, over 600 meters of window sills, various counters and vanity tops were manufactured for the project. This provided the start-up company with enough work for a long time. Another major customer in the early years was the hamburger chain Carrols.

Design first from the very beginning

Ulla had a solid background in art and, before founding Durat, had worked for one of Finland's most renowned interior designers, Pirkko-Liisa Topelius. That is why the importance of design has been emphasized in product development from the very beginning. The goal was, and still is, to develop a material that would be suitable for decorating even the most demanding interiors, both in terms of quality and visual appeal.

“I consulted Pirkko-Liisa Topelius when I was putting together the original colour chart. Based on her tips, we started with the colours that architects always go for: white, black, and various shades of grey. The accent colours in the palette were pure red, blue, green, and yellow,” Ulla explains.

Later, she tinted colours according to designers requests and those colours were added to the collection. Colours are a big part of what makes Durat stand out. The selection is exceptionally wide, with over a thousand different standard colours and patterns to choose from. And designers can still get custom colours for their projects.

A completely new addition to the colour palette was made in 2018 with the launch of the Durat Palace collection created by Kaori Pi of the Dutch design agency Most Collective. Its special feature was larger-sized color speckles, which are dyed with gently glowing natural colour pigments. They are manufactured in a Dutch paint mill founded in the 17th century. Artists from the Dutch Golden Age, such as Rembrandt and Vincent van Gogh, sourced the colours for their masterpieces from the same factory.

The emphasis on design has also been evident in Durat's brand identity. For the first twenty years, graphic designer Sissu Muhujärvi nurtured and guarded the company's visual identity and was responsible for its development. As a part of the brand refresh in 2020, the lead responsibility was transferred to Päivi Helander, who was selected as Graphic Designer of the Year 2025, among other things.

Bold trade fair appearances brought great visibility to a small company

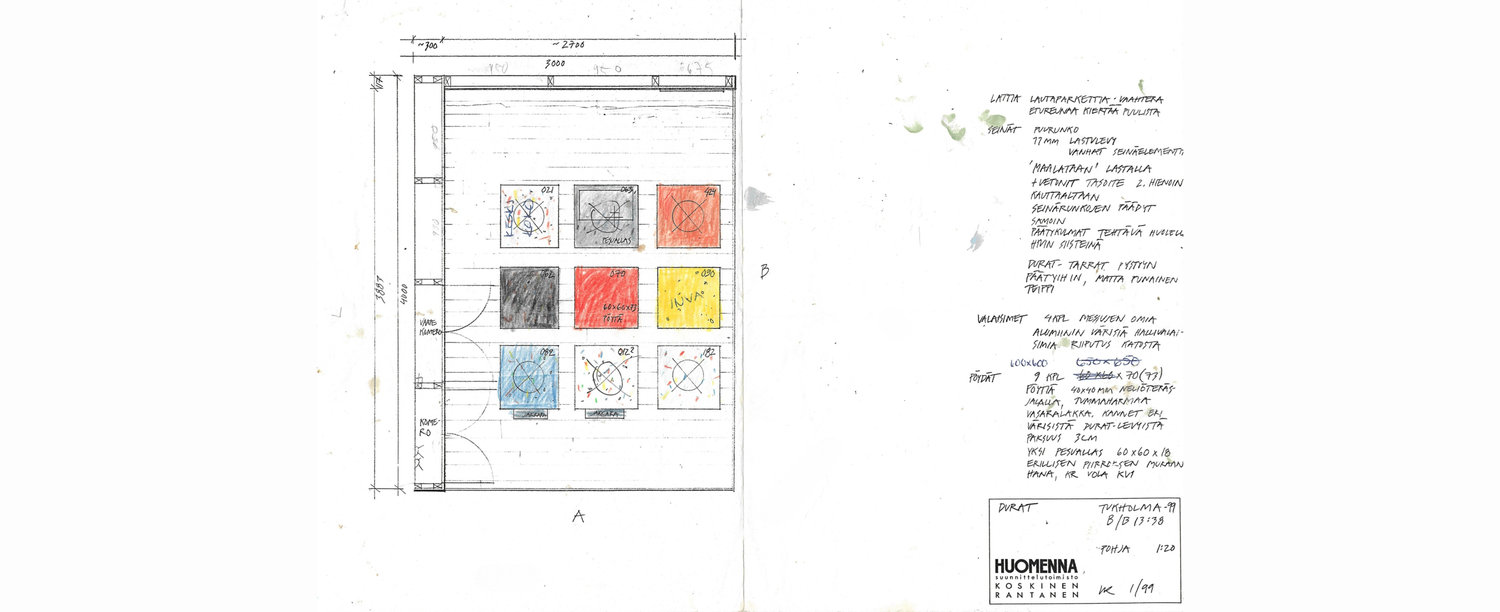

At the start of the 21st century, Durat set its sights on the international market. The company participated in the Finnish Habitare fair in 1998, and Ulla found a young, up-and-coming couple, Ulla Koskinen and Sameli Rantanen, to design the exhibition stand.

Once experience was gained in the domestic market, the next step was Stockholm Furniture Fair in 1999. The stand was again designed by the designer duo Koskinen-Rantanen.

Under the leadership of Ulla Tuominen, product design has always focused on strong design expertise. The company boldly entered the design fairs, although solid surface manufacturers usually attended material fairs.

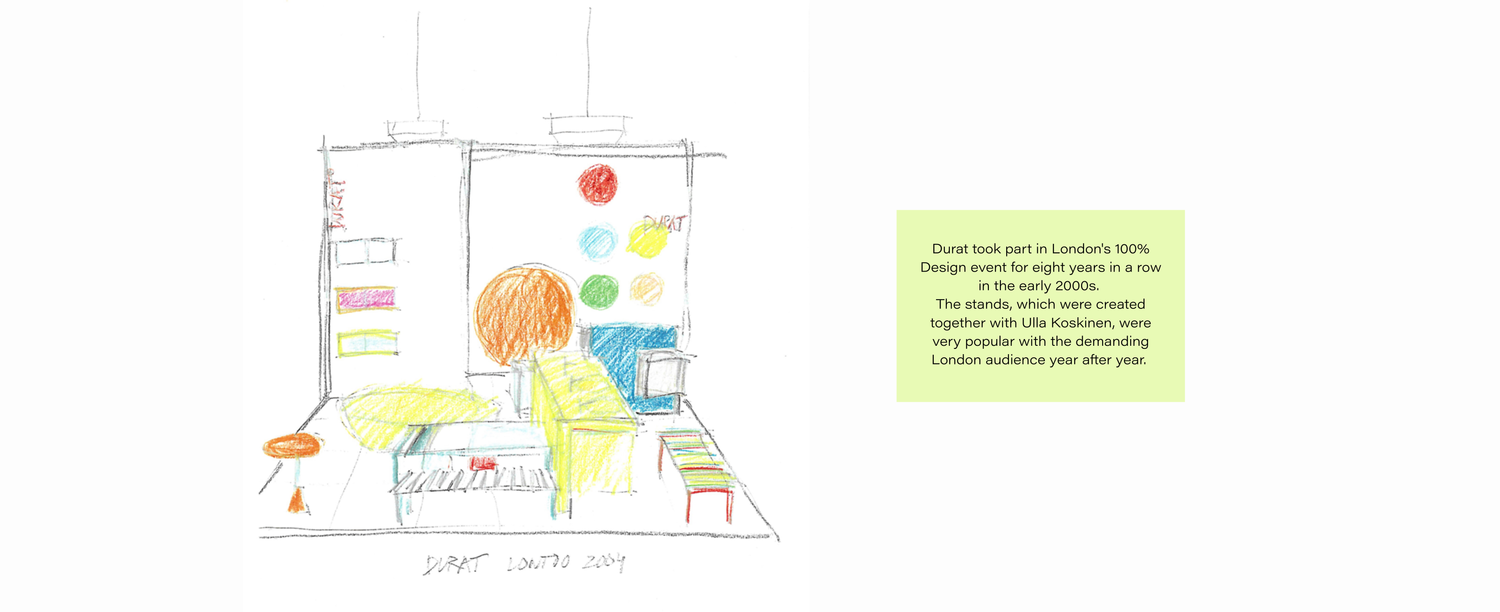

Durat participated at the 100% Design event in London for the first time in 2000. This was an event where participants were carefully selected – not just anyone could join. The stand was built around the Design Collection furniture range. We participated in the event for eight years in a row.

“The red Block sink, designed by Ulla Koskinen, with its box-like design and made from recycled materials, and the entire stand left the London audience speechless. The labyrinthine space was bustling with people and after the event inquiries came in from all over the world,” recalls Ulla Tuominen.

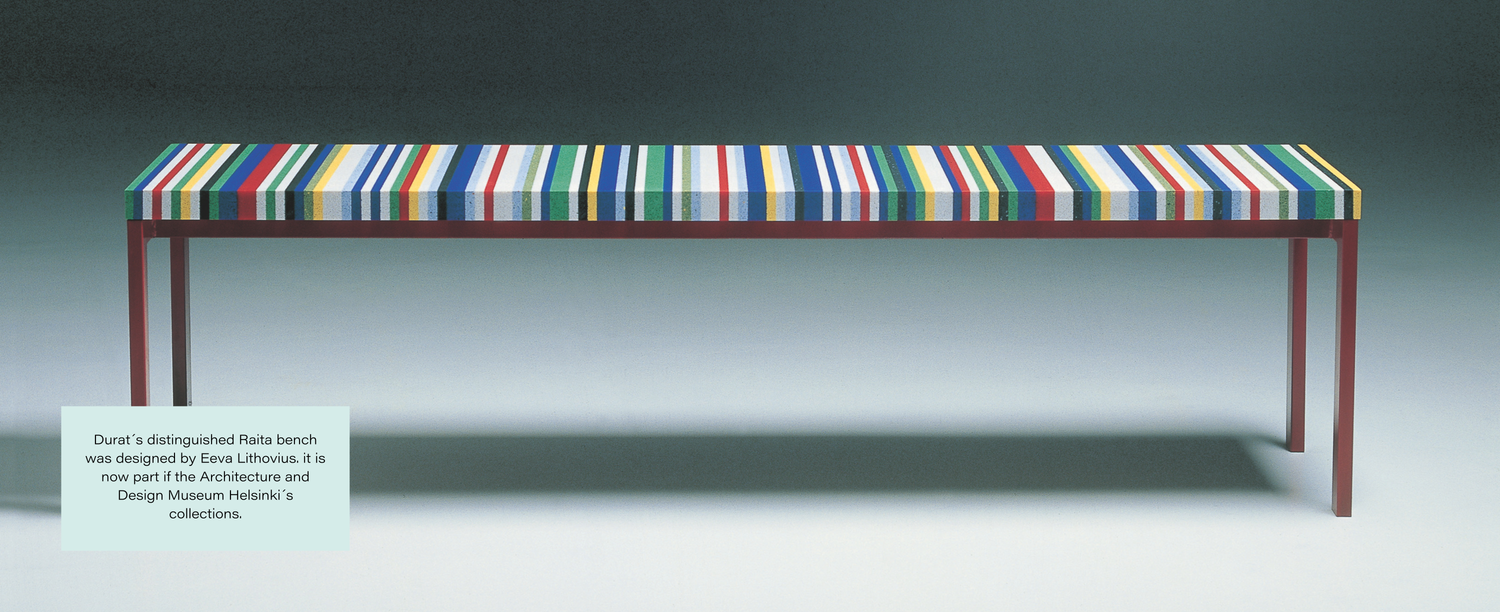

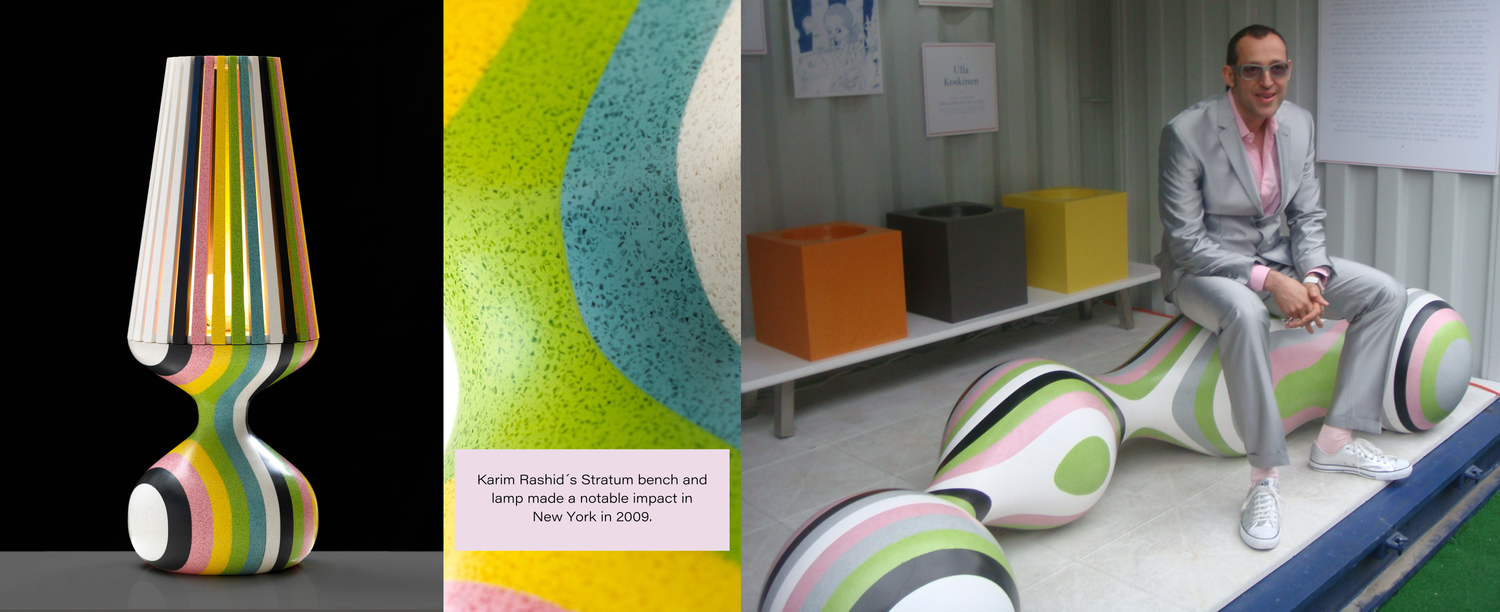

Over the years, we have collaborated with many leading figures in the field of furniture design. Block was followed by Soikko bathtubs and other basins, bathtubs, benches and tables. In addition to Ulla Koskinen, the designers behind Durat furniture include Eeva Lithovius, Esa Vesmanen, the Arup design agency, Karim Rashid and Linda Bergroth.

Durat's focus on design has succeeded in raising its profile and setting it apart from its competitors. It gained column space in major design magazines such as WallPaper, Elle, Frame and numerous other international publications. The publicity was also noticed by Finnish designers, and many of them also found Durat in their designs.

The company has always believed in its own work and presented it with pride. For example, during the Wanted Design event in New York, future CEO Heikki Karppinen, then in his twenties, packed a Block basin on his back and toured Manhattan's major American design agencies to present the product.

“As a result of that tour, I got in touch with the high-end Totem Gallery, which later became a Durat retailer,” Heikki Karppinen recalls his trip to bustling New York.

Larger premises in Rymättylä

In the mid-1990s, cruise ship designers, among others, discovered Durat. As orders began to pile up, the original premises just couldn't keep up. In 1996, production was moved to Rymättylä near Turku, where Kari Karppinen found a factory hall vacated by Abloy to serve as production facilities.

As order volumes grew and the move to Rymättylä took place, the machinery also had to be renewed. While attending a Solid Surface Manufacturers Association meeting in Germany, Kari heard that the Noblan brand was being discontinued and that a casting machine, which Durat needed, was for sale. Kari traveled to meet with company representatives. As the negotiations progressed, he decided to offer to buy both the brand and all the production machinery and inventory. It was a proposal that pleased the sellers. They were able to shut the whole thing down with ease.

Shortly thereafter, the factory in Rymättylä was bustling with activity. Moving trucks rolled into the yard at the same time from both the old factory in Orimattila and Germany.

Durat got the machinery it needed from Noblan, but even better, the brand itself turned out to be valuable. A German-American company got in touch with Durat and expressed interest in buying the Noblan brand. The deal was done, and Durat earned more than it had originally paid for the entire package.

In the early stages of Durat's operations, carpentry work was outsourced to subcontractors located near the Orimattila factory who had experience with solid surface materials. Mika Kirjavainen was one of the first carpenters to join the company in 1994. He later moved with the factory from Orimattila to Rymättylä and continues to work at Durat. In addition to Mika, many others have also had long careers at the company.

Durat's brand identity has been carefully cultivated over the years. The logo has been updated over time, but it still bears a strong resemblance to the original version. For the first twenty years, graphic designer Sissu Muhujärvi was responsible for developing the logo and visual identity. In 2020, the brand identity was thoroughly reviewed with the aim of clarifying it to reflect the company's current goals and values. In connection with this, responsibility for the project was transferred to graphic designer Päivi Helander.

Export development

Participation in international events has helped build a global network, which has ked to the discovery of numerous distributors in cities such as London, New York, Paris, Copenhagen, Tel Aviv, Oslo, Amsterdam and Belgium, and later also a group of distributors, who have played a significant role in increasing exports.

David Spuria, the founder of American company CaraGreen, contacted Durat in 2008. CaraGreen became Durat's first distributor worldwide.

The distributor network has been growing steadily, especially over the past six years. In 2019, cooperation began with the English company Surface Matter and the Dutch company Pyrasied. In 2021, the French company Ober Surfaces and the Italian company 3D Wall Panels joined the distributor network, followed by the German company Thomas Spahn Holzwerkstoffe in 2024 and Spanish company Matter in 2025.

With the help of Kari's contacts in China, Durat sold the factory to Ganzhou, China in 2007. In the global market, it is important for companies to understand different customs. Durat people were given excellent reminder of cultural differences when Durat's Chinese partner, Mr. Zhong, visited Finland to sign the contract. On the way from the airport, he saw a hearse in the traffic. Mr. Zhong was over the moon, as he believed the hearse would bring success to the new partnership.

Durat Ganzhou Solid Surface Ltd has the rights to sell its products to the Chinese market.

A pioneer in the circular economy and recycling

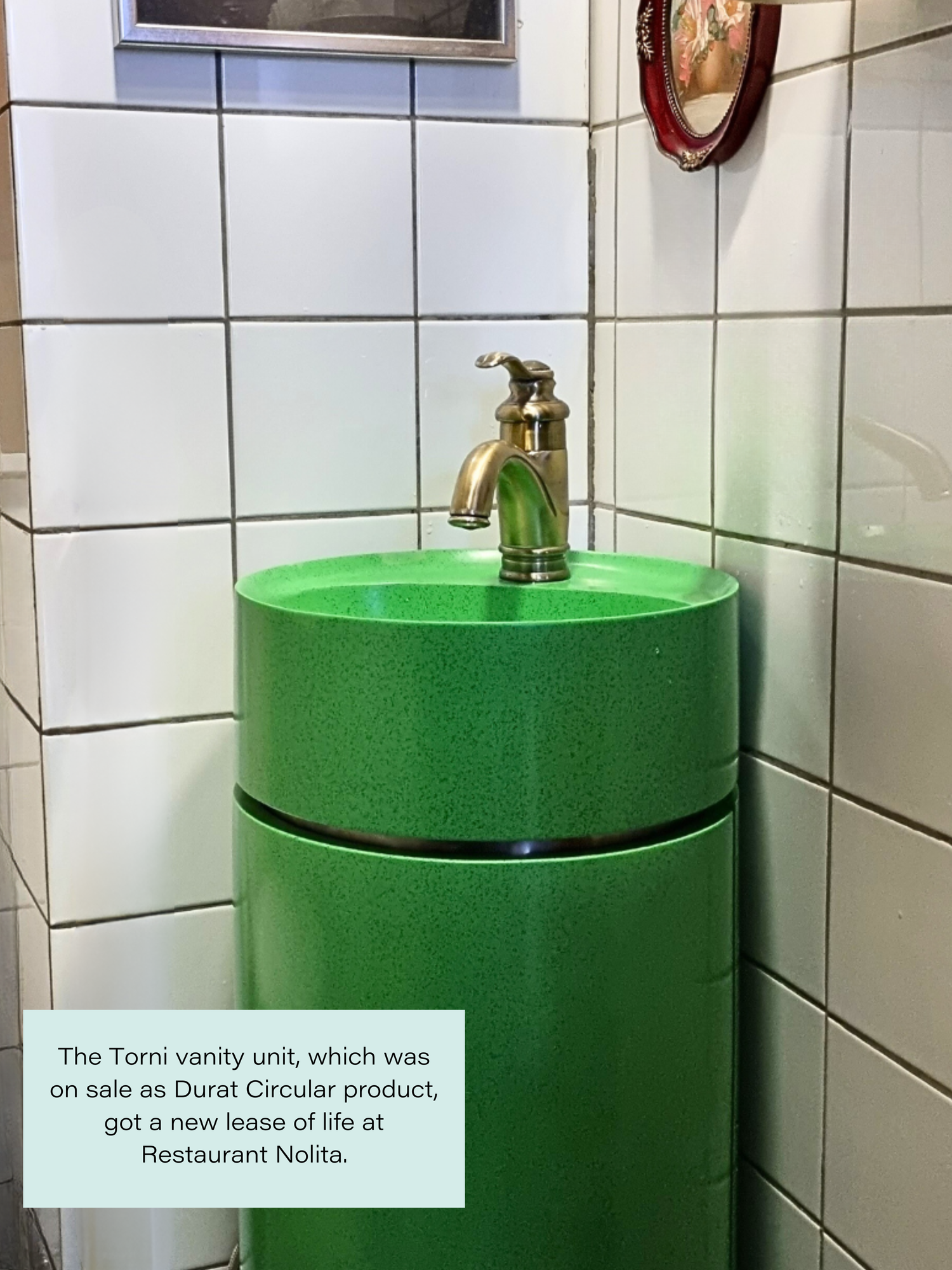

The pursuit of circular economy principles has been at the heart of Durat's operations throughout its history. Durat is committed to buying back all Durat furniture that is no longer in use. The furniture returned to us is serviced, possibly modified slightly in terms of dimensions, and sold to new users as Durat Circular products.

The goal is to manufacture products that last as long as possible and to make sure that products and materials are designed so that they can be reused, repaired and remade.

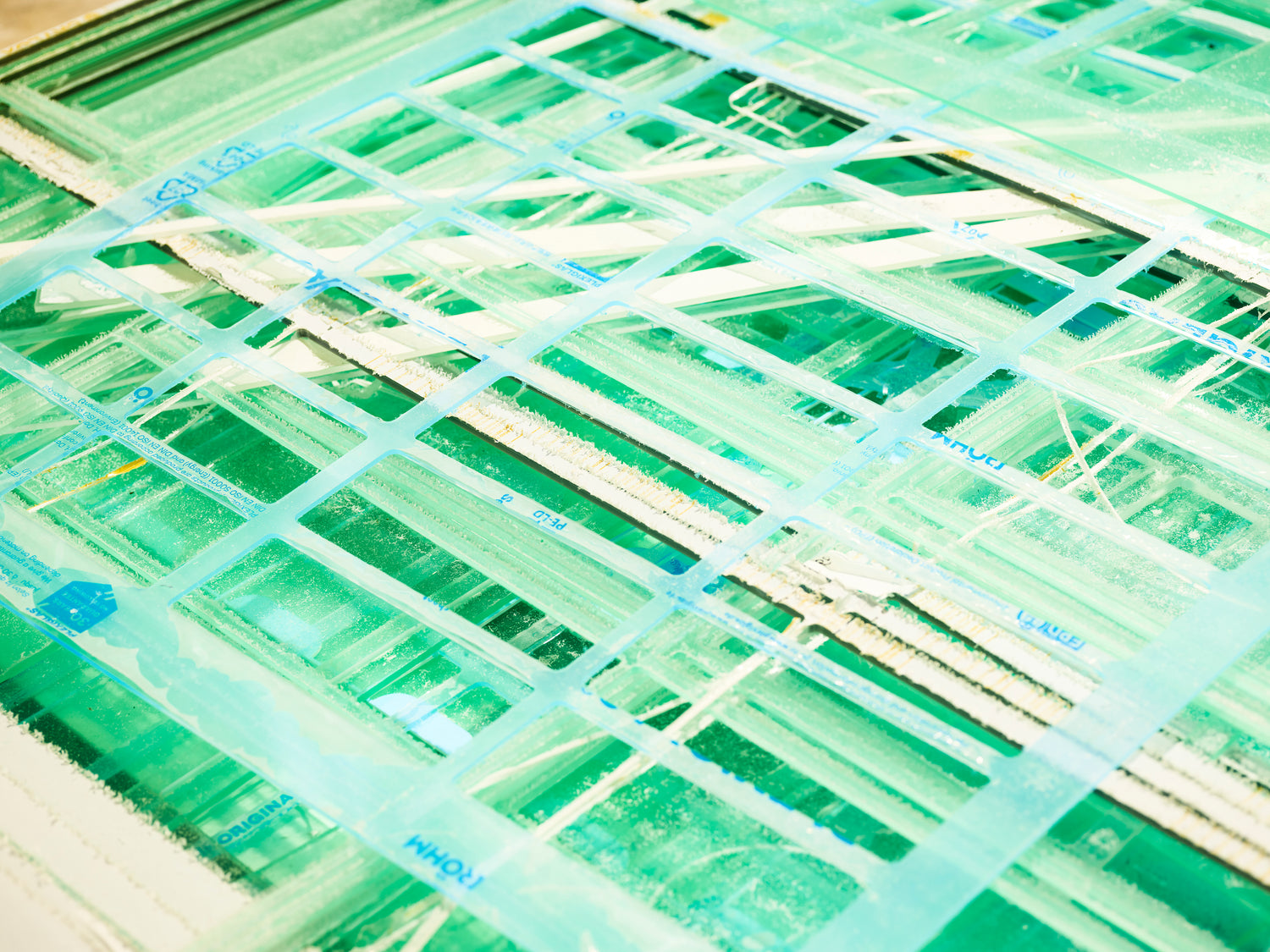

During the product development phase, a formula was sought that would maximize the proportion of recycled plastic in the product while ensuring that the product was functional and durable. Durability and maintainability are important characteristics that can significantly extend the life cycle of a product.

The recycled material used is transparent acrylic waste generated as industrial surplus. It remains a key component of Durat, but from a fairly early stage, Durat has also recycled Durat cutting waste generated in furniture manufacturing. This makes the material 100% recyclable.

Many of the Durat products manufactured in the early stages are still in use. Over the years, however, the needs of many of the original applications have changed and the concepts of the premises have been renewed. As a result, some furniture has been taken out of use, even though it is still in good condition, at least after light surface maintenance.

If the products cannot be sold as they are, they can be crushed and used as a raw material for new products.

Strengthening the circular economy as a product development goal

Back in 2020, Durat appointed Mervi Puska, PhD, as its new Head of Material Development. Puska is a polymer chemist and an expert in composites and biomaterials. The key objective of her work is to find new raw materials and operating methods that will enable Durat to further increase the use of recycled materials, strengthen its operations in line with the principles of the circular economy, and ensure that the factory's emissions are minimized.

Denis Matvienko, the Production Manager, has been with the company since 2015 and has been a key player in developing production. With his determined approach, he has helped the company meet demand while reducing costs and emissions. Durat's production took a huge leap forward when the new casting line installed at the factory in 2025. This will increase the factory's production capacity.

The future

In 2017, the CEO position was passed on to a new generation when Heikki Karppinen took over as CEO of Durat. Under Heikki's leadership, Durat wants to strengthen its work in recycling and material development.

“Our goal is to play a key role in moving interior design from a linear economy towards circular economy practices,” Heikki outlines.